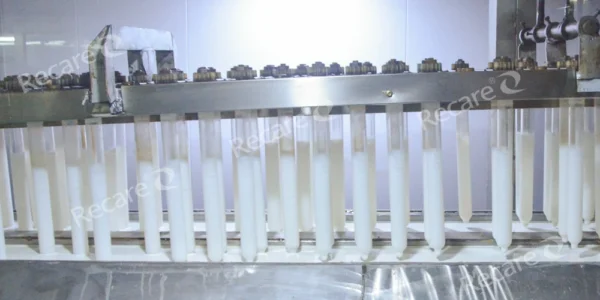

This project includes various machines involved in the production process of condoms, from storing raw materials, pre vulcanization of latex raw materials, to impregnation molding, vulcanization, quality testing, and aluminum foil bag packaging of condoms.From the film sealing machine for boxes to the wrapping machine for carton.

| External size of production line | 55.4m*3.2m*2.8m |

| Main engine | 2.2KW×3sets |

| Thermal energy consumption (steam) | 1T/h |

| Power Consumption | 70KW |

| Water consumption | 6T/h |

| Mold spacing | 80mm |

| Chain linear velocity | 0—10m/min |

| Molds | 4800pieces |

| Daily Production Capacity per line | 0-360000 pieces of condom (Can be adjusted according to customer needs) |

| Soft Water | 10T/24h |

| Quality guarantee | one year |

| Install | 3engineers for 2months |

| Production cycle | 60days |

Production technical training cycle for 20 days. The training ensures that personnel are fully familiar with system operation and can effectively handle any issues, achieving efficient management and routine maintenance.

©China Tianjin Recare Co., Ltd.

Recare has designed, manufactured, and installed condom production lines in various regions.