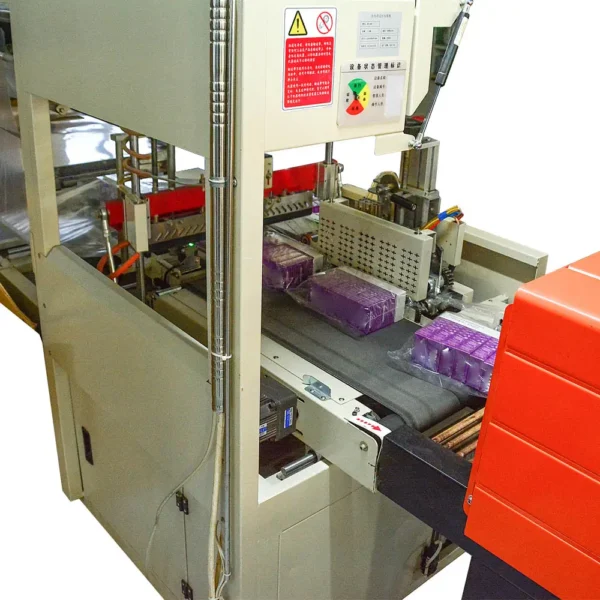

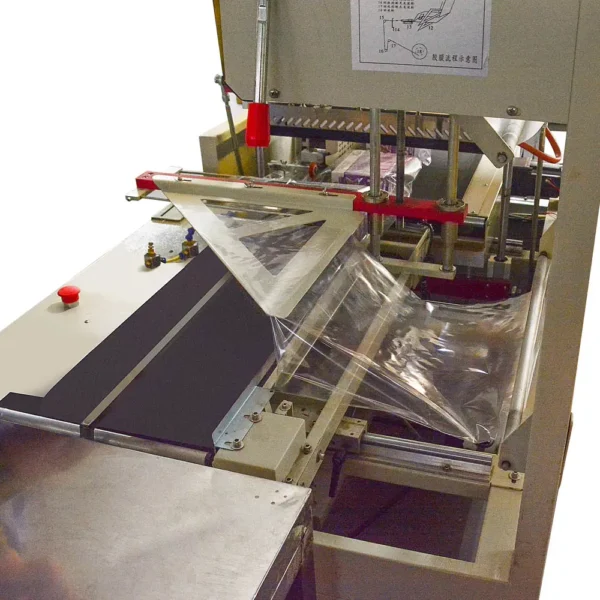

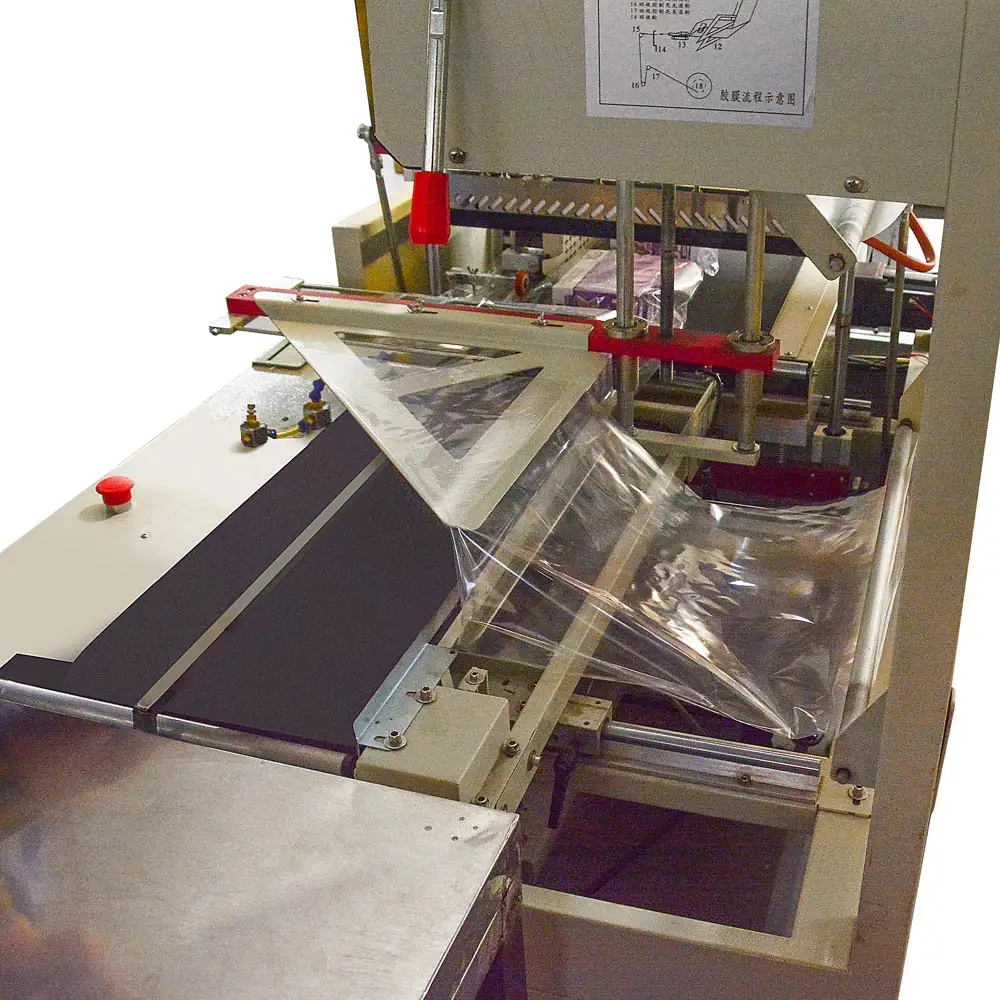

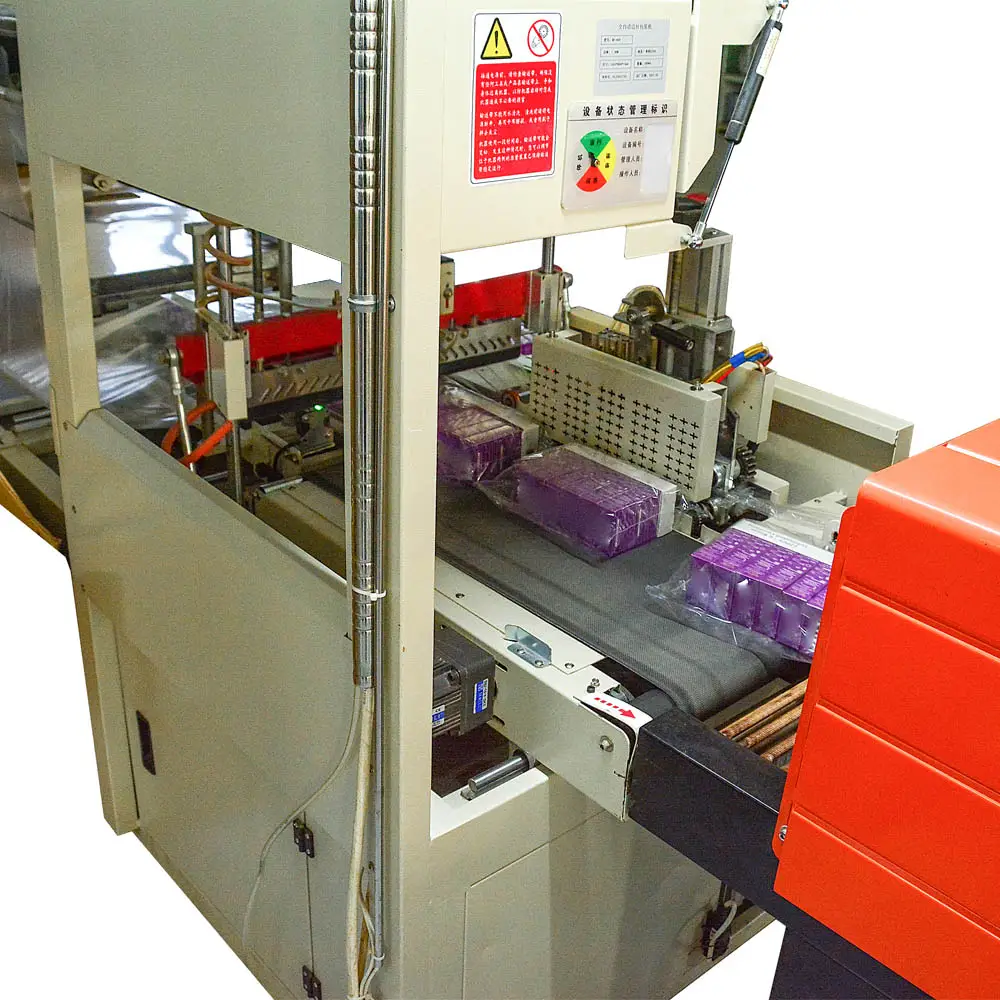

The fully automatic and unmanned “!” type sealing and cutting machine is widely used in the assembly line operation of mass production packaging, with high work efficiency. It has an automatic film feeding and punching device, a manually adjusted film guiding system, and a manually adjusted feeding and conveying platform, suitable for products of different widths and heights.

| BTA-450 | BTA-500 | |

| Max Packing Size | (L+H)=500mm(W+H)=430mm(H)=130mm | (L)700x(W)450x(H)250mm |

| Max sealing Size | (L)550x(W)450mm | (L)1200x(W)500x(H)300mm |

| Packing Speed | 15~30packs/min | 30~50packs/min |

| Electric Supply & Power | 220V 50Hz 1.3kw | 380V/50Hz12kw |

| Air Pressure | 5.5kg/cm3 | |

| Machine Weight | 300kg | 220kg |

| Overall Dimensions | (L)1850x(W)1000x(H)1600mm | (L)1350x(W)750x(H)1500mm |

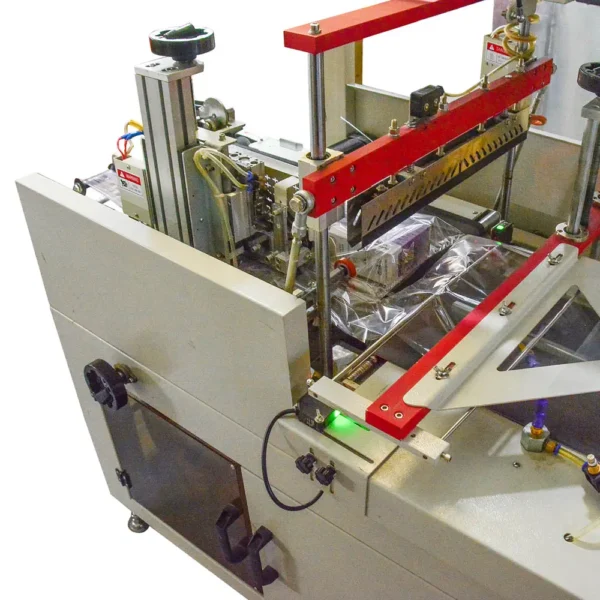

1.Adopts heat resistant alloy cutter plated Teflon,results in good sealing ,withoutmelting the film and any smoke pollution.

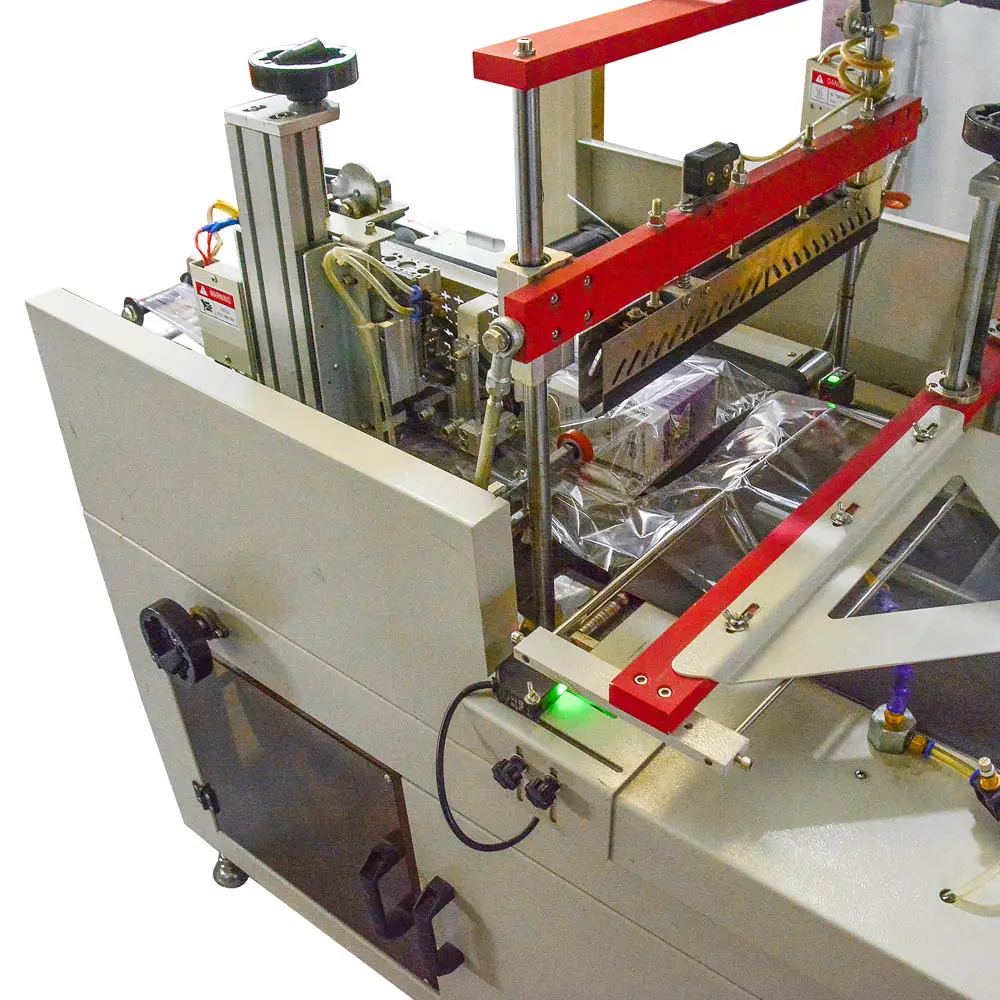

2.Assembles one horizontal and one erect sensor for the entrance to the sealer it iseasy to switch over ,even for some thin products,it is also easy to pack them.

3.The length of film feeding,controlled by magic eye and counter,also fixes aninductive motor for collecting wasted film automatically.

4.When pack different sizes of products ,it is simple to adjust,need not to exchangeany molds or any bag making device.

5.To pack different size of products together for sales promotion effect.

6.Adopts OMRON digital temperature controller with PlD function,sealingtemperature is extremely sensititive and accurate,can set temperature optionallythe cutter itself has a protective function,avoid from damage the products.

7.The machine fixes an organic safty glass cover,with alarm function,so that theoperator is safe.

8.The machine can be connected with the production line, which is no needadditional operators.

©China Tianjin Recare Co., Ltd.

Recare has designed, manufactured, and installed condom production lines in various regions.