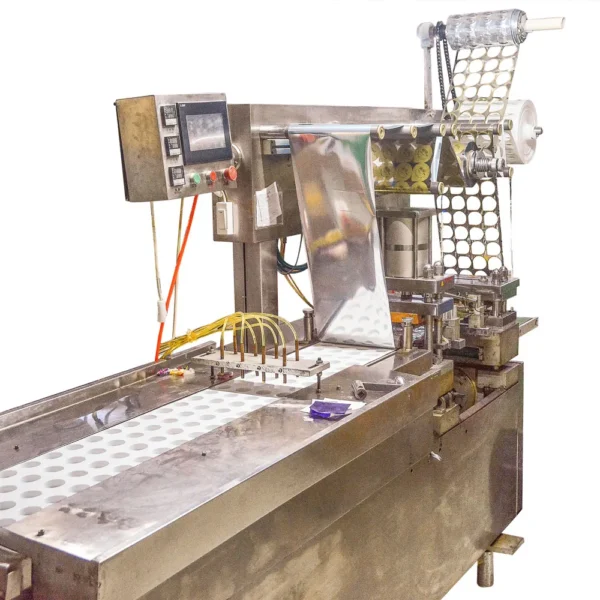

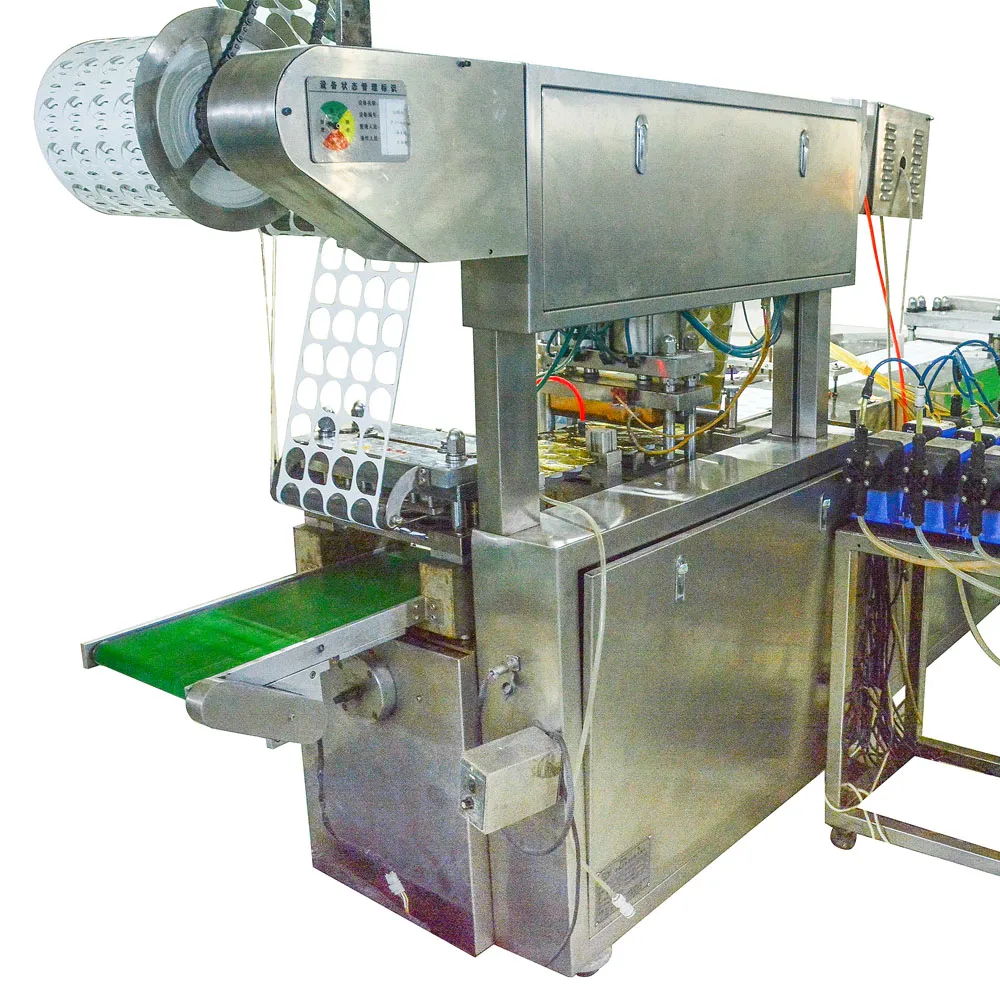

The blister packaging machine integrates flat forming and heat sealing into one blister packaging machine, which can be used in two ways: aluminum-plastic and aluminum aluminum packaging. It is suitable for packaging various specifications of sugar coated tablets, plain tablets, capsules, capsules and other drugs, and can also be used for condom packaging.

| Punching Frequency | 6-50 strokes/minute |

| Single Row Quantity | 4 (1 cut=4*2) |

| Production Capacity | 35,000/hour |

| Maximum Forming Area and Depth | 240x170x26mm |

| Standard Stroke Range | 40-160 mm (customizable) |

| Standard Plate Size | 80x57mm (customizable) |

| Air Pressure | 0.4-0.6 MPa |

| Air Consumption | (Air Compressor) ≥0.3m³/min |

| Total Power Supply | 380V/220V 50Hz 6.2KW |

| Main Motor Power | 1.5KW |

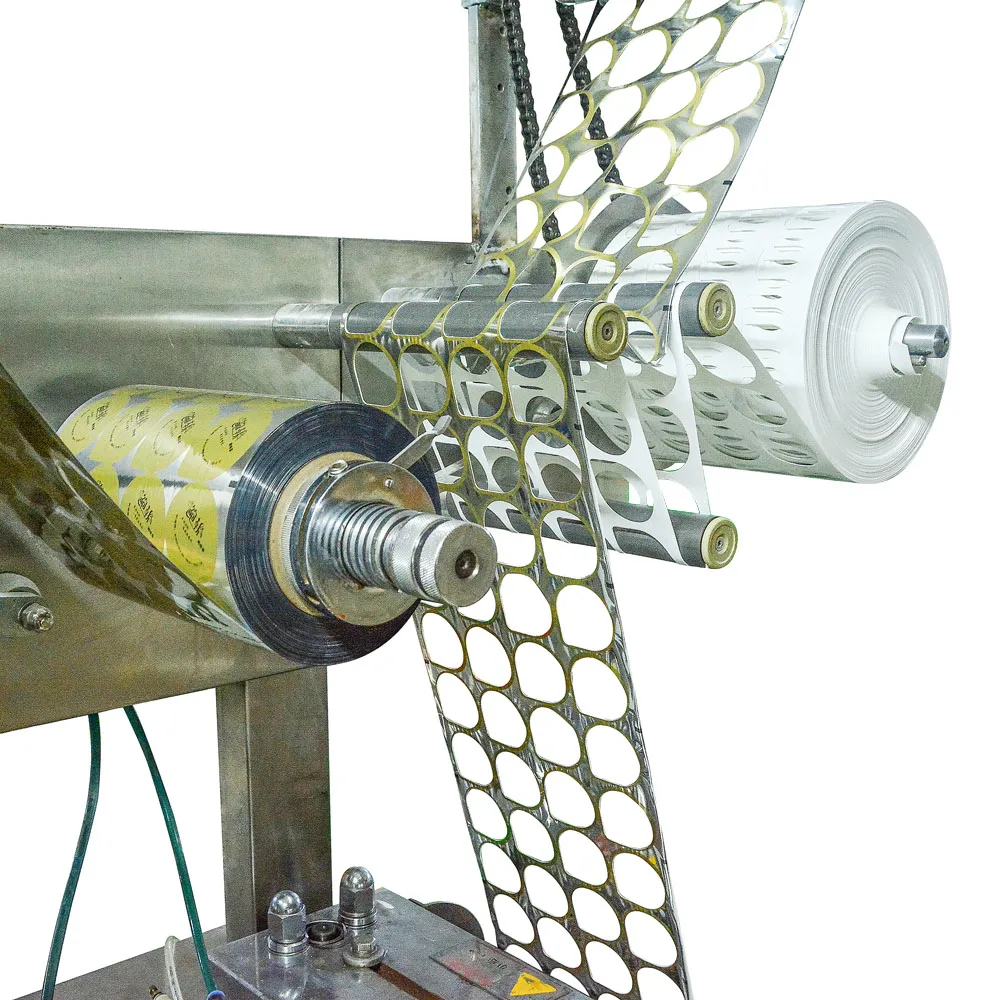

| PVC Rigid Sheet | 0.15-0.5 x 250mm wide |

| PTP Aluminum Foil | 0.02-0.035 x 250mm wide |

| Dialysis Paper | 50-100g x 250mm |

| Mold Cooling | Tap water or circulating water |

| Dimensions | 2750*950*1800mm (LxWxH) |

| Package Dimensions | 3100*1150*2300mm |

| Weight | N.W.440 kg, G.W.490 kg |

| Noise Level | <75dBA |

The machine has strong adjustability, with the main motor variable frequency speed regulation. It can flexibly set the punching frequency according to the stroke, material filling difficulty, etc. The traction mechanism is independently controlled by a servo motor, and the stroke length can be conveniently set through the PLC control panel

©China Tianjin Recare Co., Ltd.

Recare has designed, manufactured, and installed condom production lines in various regions.