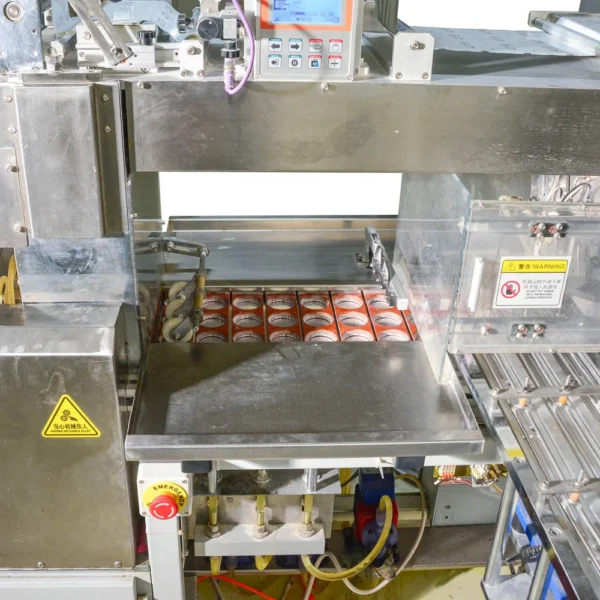

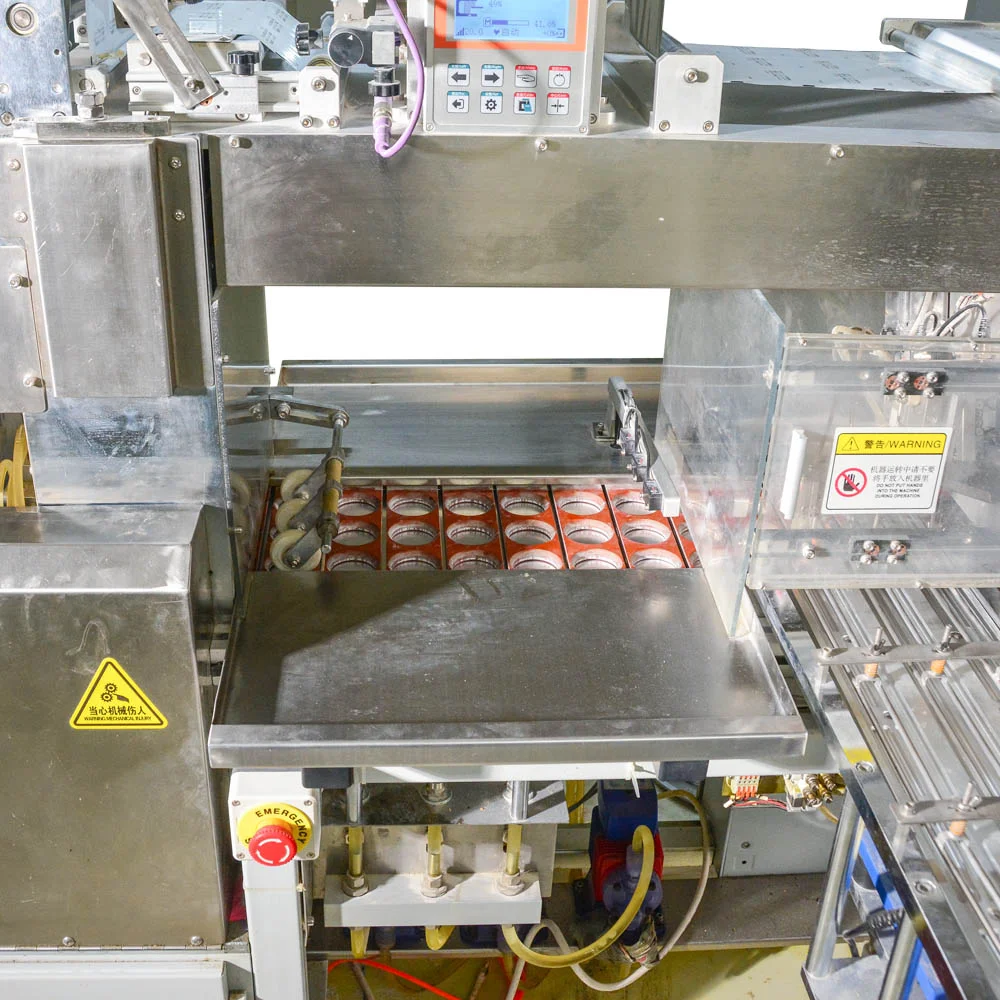

The packaging machine is equipped with a fully automatic sorting device, which uses principles such as centrifugal force to place the condoms to be packaged in the second rotating disc of the rotating sorting section, transfer them to the first rotating disc, and then send them to the linear feeding disc, so that the condoms are evenly and orderly output, avoiding product stacking and disorderly stacking, and not affecting the curling effect of the condoms.

| Feature | Value |

| Equipment Type | Recare Auto Condom Foiling Machine |

| Output | 120 – 150 packs per minute |

| Packaging Specification | 6060mm, 5050mm |

| Power | 1.8 kW |

| Air Pressure | 5 kg/cm² |

| Dimensions (L x W x H) | 2700 mm x 1850 mm x 1600 mm |

| Weight | 900 kg |

| Brand of Pneumatic Components | SMC |

| Brands of Electrical Components | Omron, Delta, Schneider, Autonics |

| Brands of Motors | TWT, Delta |

| Oil Pump | Precision metering pump with an accuracy of 0.05 mg |

1. Labor Saving: Equipped with an automatic supply system, one operator can operate 2 to 4 machines.

2. High Efficiency: Adopting a three-row design, the equipment can operate stably, and the speed can reach 135 pieces

3. Less Downtime: Compared with single connected machines, the equipment runs continuously and smoothly. The speed of each channel is relatively low, and the Overall Equipment Effectiveness (OEE) of the equipment can reach over 90%.

4. Easy Maintenance: The equipment has a simple structure, high stability, and low maintenance cost.

5. High Degree of Automation: It is equipped with devices such as automatic feeding, goods pressing detection, belt control detection, waste removal, and waste film cutting. Encoders are used instead of cams, which makes it convenient to accurately and intuitively adjust the action time and position. The advanced design reduces the contact between mechanical components and products, reducing the risk of holes.

6. High-quality Products: The special feeding structure ensures that products can smoothly enter the sealing system without jamming or pressing of goods. The high-precision metering pump ensures accurate dosage, and there is a silicone oil detection and alarm system. Devices such as aluminum foil joint detection can automatically remove various types of waste products.

7. Printing Types (Optional): It can provide various coding methods such as Ink jet, Thermal Transfer Overprinting (TTO), and Heat Ink.

8. Aluminum Foil Edge Correction Device (Optional): An aluminum foil edge correction device can be provided to ensure the accurate position of the aluminum foil during the production process.

©China Tianjin Recare Co., Ltd.

Recare has designed, manufactured, and installed condom production lines in various regions.